10 mm to SAE Conversion: Your Metric Nightmare Ends Here

So you're knee-deep in a project, wrench in hand, and suddenly you realize the bolt you need is in millimeters. But your socket set? Oh, it's singing the sweet song of SAE. Don't panic, because we're diving deep into the wild world of 10 mm to SAE conversion.

The struggle is real. It's like trying to order a pizza in Italian when all you know is "pizza pie." But fear not, because just like mastering the art of ordering a Margherita extra crispy, understanding the conversion from 10 mm to its SAE equivalent is crucial for any DIY enthusiast, mechanic, or frustrated homeowner staring down a flat-pack furniture assembly manual.

Why is this seemingly simple conversion such a big deal? Because using the wrong size can lead to stripped bolts, rounded-off nuts, and a whole lot of frustration. We've all been there, staring at a mangled bolt and questioning our life choices. And let's not forget the universal truth: nothing kills a project's vibe faster than having to make an emergency run to the hardware store because of a metric-imperial system mismatch.

While a 10 mm wrench might seem close enough to some SAE sizes, don't be fooled by the siren song of "close enough." Forcing the wrong size can lead to damage, and nobody wants that. This is where understanding the basics of conversion becomes your secret weapon.

Now, before you grab your calculators and start memorizing decimal points, let's break down the conversion process. What exactly is the SAE equivalent of 10 mm, and how can you be sure you're using the right tool for the job? Get ready to conquer those metric-to-imperial woes!

The closest SAE equivalent to 10 mm is 3/8 of an inch. Now, before you run off thinking you've cracked the code, remember that this is just an approximation. The actual conversion is 10 mm = 0.3937 inches. While 3/8 inch (0.375 inches) is close, it's not exact.

So, what does this mean for you in the real world? It means that while a 3/8 inch wrench might work in a pinch for a 10 mm bolt, it's not ideal. Forcing the issue could damage your tools or the fastener itself.

The best practice? Invest in a set of metric wrenches and sockets. Trust us, your future self will thank you for it. But hey, we get it. Sometimes you need a quick fix, and that's where understanding the conversion comes in handy.

Advantages and Disadvantages of Converting from Metric to SAE

Let's break down the pros and cons of grappling with metric-to-SAE conversions:

| Advantages | Disadvantages |

|---|---|

| Sometimes necessary when working with older equipment or parts that use SAE measurements. | Conversions are often approximate, not exact, which can lead to inaccuracies and potential damage. |

| Understanding the conversion allows you to make informed decisions when a precise metric tool isn't available. | Can be confusing and time-consuming, especially for complex measurements. |

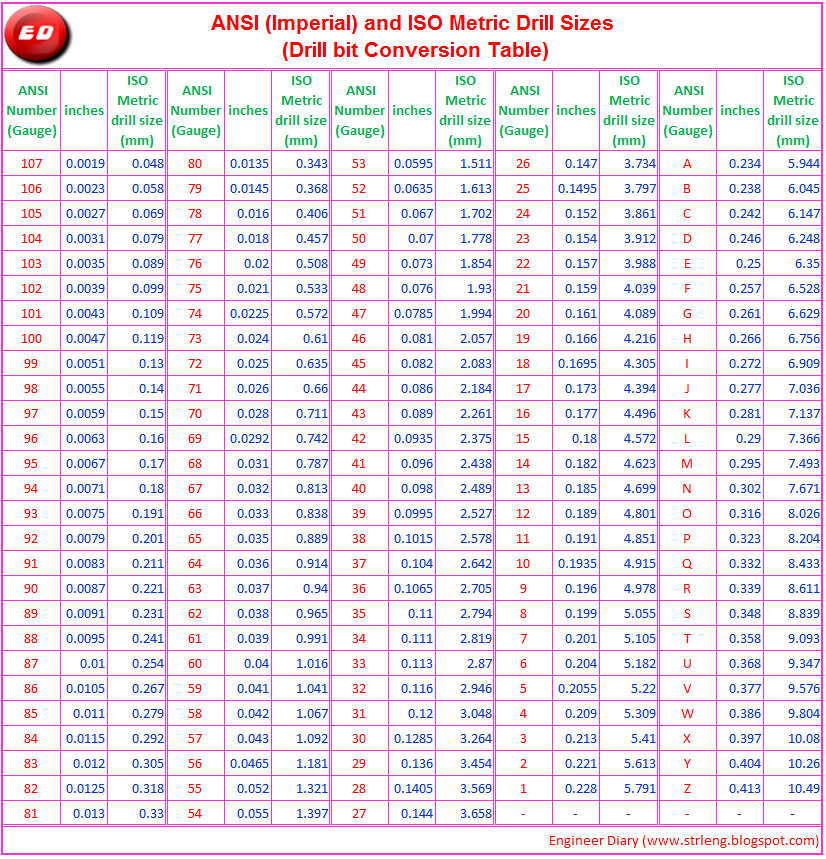

Navigating the world of measurements can feel like deciphering ancient hieroglyphs. But armed with the knowledge of 10 mm to SAE conversion, you'll be well-equipped to tackle any project that throws your way. Remember, the key is understanding the basics and using the right tools for the job. And when in doubt, there's no shame in consulting a conversion chart or app – they're your secret weapon in the battle against metric-imperial system mayhem.

Amp picking up radio signals mystery solved

Unveiling the charm the allure of bobbie rae carter on hsn

The eloquent language of digital belonging