Keep Your Outboard Cool: The Essential Guide to Water Pump Impellers

Is your outboard motor running hot? Overheating can spell disaster for your boat's engine, leading to costly repairs and lost time on the water. One tiny component plays a crucial role in preventing this nightmare scenario: the outboard water pump impeller. This often-overlooked part is the heart of your engine's cooling system, and understanding its function is vital for every boat owner.

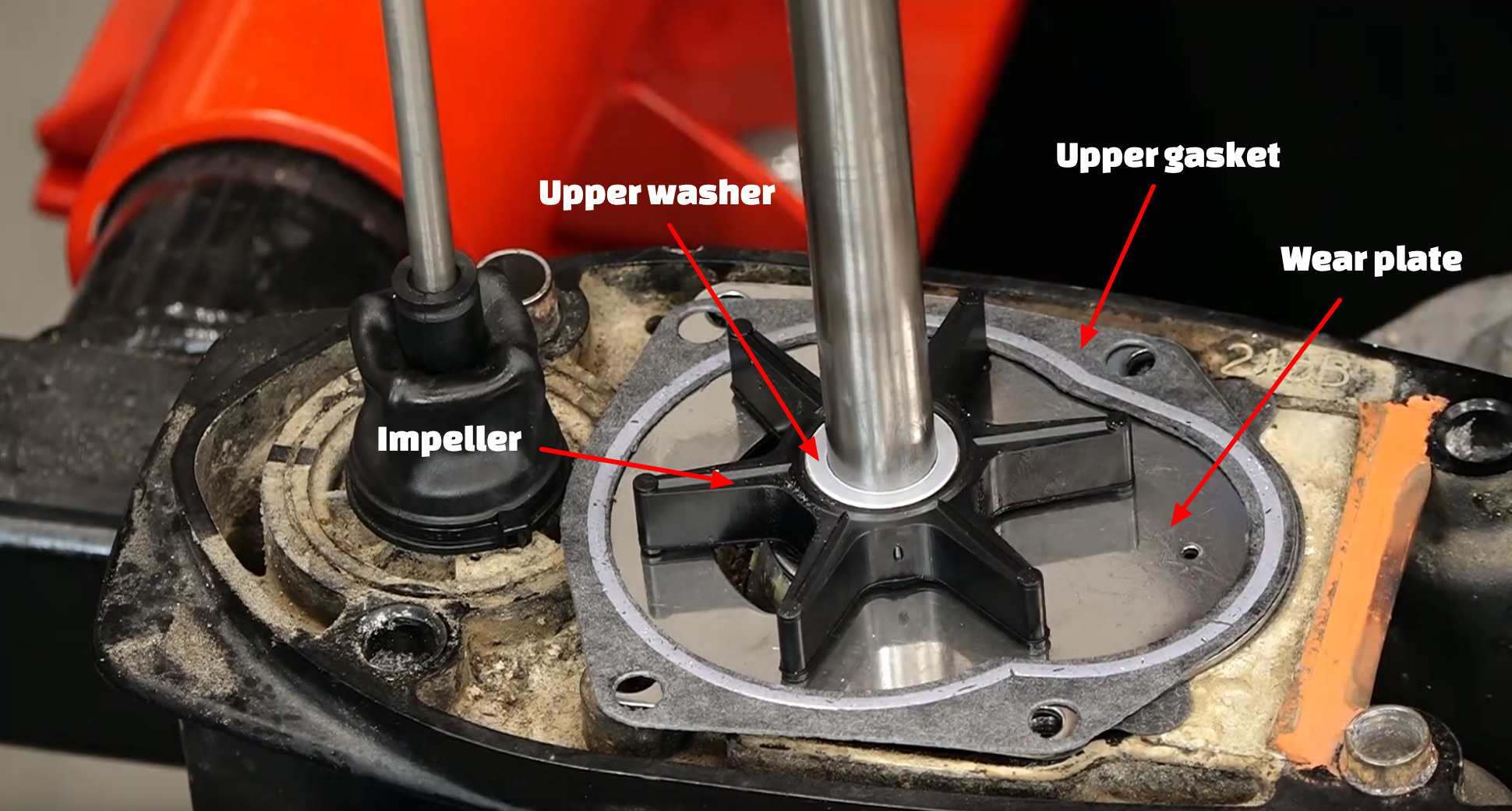

The outboard water pump impeller, often referred to as just the "impeller," is a small, flexible rubber component located within the outboard's water pump. It spins rapidly, drawing water from the surrounding environment and pushing it through the engine block to dissipate heat. Without a properly functioning impeller, your engine can quickly overheat, causing significant damage.

The history of the outboard water pump impeller is intertwined with the development of the outboard motor itself. As engines became more powerful, the need for efficient cooling systems became paramount. Early impellers were often simple designs, but they evolved alongside engine technology, becoming more durable and efficient. Today's impellers are typically made from specialized rubber compounds that can withstand the harsh marine environment and the high rotational speeds required for effective cooling.

The importance of a functioning water pump impeller cannot be overstated. It's the linchpin of the cooling system, preventing overheating and ensuring the longevity of your outboard. A damaged or worn impeller can lead to a cascade of problems, ranging from reduced performance to catastrophic engine failure. Regular inspection and replacement of the outboard impeller are essential preventative maintenance tasks.

One of the most common issues related to outboard water pump impellers is wear and tear. Over time, the impeller blades can become brittle, cracked, or even broken due to constant flexing and exposure to chemicals and debris in the water. Another common problem is impeller damage caused by running the engine dry, which can quickly melt or deform the impeller. Impeller failure can also be caused by debris such as sand or fishing line becoming lodged in the water pump housing, obstructing the impeller's rotation.

A well-maintained water pump impeller offers numerous benefits. First and foremost, it ensures proper engine cooling, preventing overheating and extending the engine's lifespan. Secondly, a healthy impeller contributes to optimal engine performance by maintaining the correct operating temperature. Finally, a functioning impeller can save you money on costly repairs by preventing major engine damage caused by overheating.

Creating an action plan for impeller maintenance is simple. Inspect your outboard water pump impeller at least once a year, or more frequently if you operate your boat in harsh conditions. Always carry a spare impeller onboard in case of unexpected failure. When replacing the impeller, be sure to use the correct part for your specific outboard model.

Advantages and Disadvantages of Rubber Impellers

| Advantages | Disadvantages |

|---|---|

| Relatively inexpensive | Susceptible to wear and tear |

| Easy to replace | Can be damaged by running dry |

| Effective at cooling in most conditions | Performance can degrade over time |

Best Practices for Outboard Water Pump Impeller Maintenance:

1. Regular Inspection: Inspect the impeller visually for cracks, tears, or other damage.

2. Flush the Cooling System: After each use in saltwater, flush the cooling system with fresh water to remove corrosive salts and debris.

3. Carry a Spare: Always have a spare impeller onboard.

4. Proper Installation: Ensure the impeller is installed correctly and securely.

5. Use the Correct Impeller: Use the manufacturer-recommended impeller for your outboard model.

Real-World Examples:

1. An angler noticed decreased performance and higher engine temperatures. Upon inspection, he found a worn impeller, replaced it, and restored normal engine function.

Frequently Asked Questions:

1. How often should I replace my outboard water pump impeller? Generally, once a year or more often in harsh conditions.

Tips and Tricks:

Lubricate the impeller with glycerin or silicone grease before installation to ease fitting and prevent damage during initial startup.

The outboard water pump impeller, though small, is a critical component for any boat owner. Its proper function is paramount to maintaining the health and longevity of your outboard motor. Regular inspection, preventative maintenance, and understanding the signs of impeller problems can save you from costly repairs and ensure enjoyable time on the water. By following the best practices outlined above and being proactive about impeller care, you can keep your outboard running cool and efficiently for years to come. Remember, a small investment in impeller maintenance can prevent significant expenses in the future. Don't overlook this crucial component – your outboard will thank you! Take action now to protect your investment and enjoy trouble-free boating.

Decoding braxton hicks your guide to practice contractions

Cleaning company names the ultimate guide to choosing yours

Kristi noems smile transformation exploring the buzz