The Silent Sentinel: Unraveling the Mysteries of the Electric Oil Pressure Gauge

In the intricate symphony of a combustion engine, where pistons dance and gears mesh, a silent guardian stands watch, tirelessly monitoring a vital lifeblood: oil pressure. This unsung hero, the electric oil pressure gauge and its accompanying sending unit, plays a crucial role in ensuring the longevity and smooth operation of our vehicles.

Imagine a world without this vigilant sentinel. The engine, starved of lubrication, would quickly succumb to friction, heat, and ultimately, catastrophic failure. The electric oil pressure gauge acts as an early warning system, alerting us to potential problems before they escalate into costly repairs. It provides a window into the heart of the engine, allowing us to glimpse the vital flow that keeps everything running smoothly.

The transition from mechanical to electric oil pressure gauges marked a significant advancement in automotive instrumentation. Early gauges relied on a direct mechanical link between the oil gallery and the gauge itself, often involving a cumbersome tube filled with oil. Electric systems, on the other hand, offer greater flexibility, accuracy, and safety by utilizing a sending unit to convert oil pressure into an electrical signal. This signal is then transmitted to the gauge, providing a convenient and reliable reading.

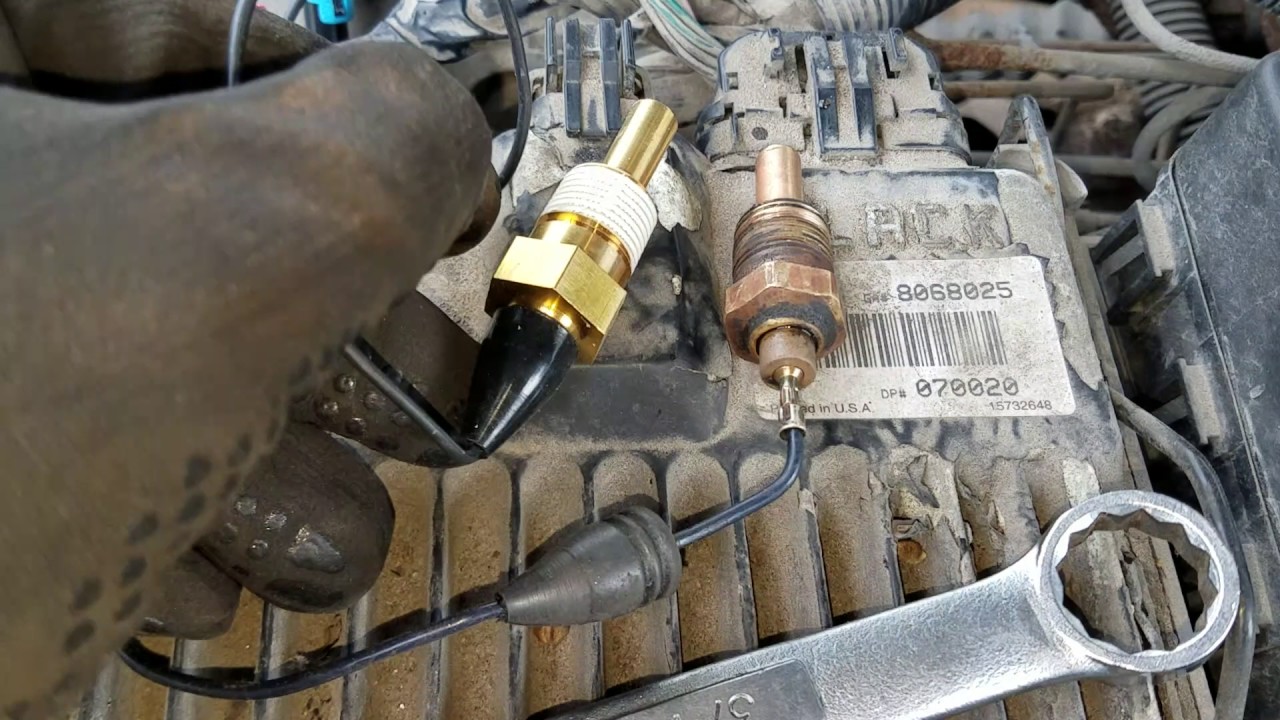

The sending unit, a small but mighty component typically located near the engine's oil filter, is the linchpin of this system. It contains a pressure-sensitive diaphragm that moves in response to changes in oil pressure. This movement alters the resistance of a variable resistor, modulating the electrical signal sent to the gauge. The gauge, in turn, interprets this signal and displays the corresponding oil pressure reading. A malfunctioning sending unit can lead to inaccurate readings, potentially masking serious engine problems.

Understanding the workings of this essential duo, the electric oil pressure gauge and sending unit, empowers us to take proactive steps in maintaining our vehicles. It transforms us from passive passengers to informed operators, capable of recognizing and addressing potential issues before they wreak havoc on our engines.

One of the primary issues associated with electric oil pressure gauges is faulty wiring or connections. A loose or corroded connection can disrupt the signal between the sending unit and the gauge, leading to erratic readings or complete failure. Another common problem is a malfunctioning sending unit, which may become clogged or wear out over time.

Three key benefits of electric oil pressure gauges are their accuracy, convenience, and safety. Electric gauges provide more precise readings compared to their mechanical counterparts, allowing for better monitoring of engine health. Their remote installation eliminates the need for bulky oil lines, simplifying installation and improving aesthetics. Furthermore, electric systems eliminate the risk of oil leaks, enhancing safety.

Advantages and Disadvantages of Electric Oil Pressure Gauges

| Advantages | Disadvantages |

|---|---|

| Accuracy | Potential for electrical issues |

| Convenience | Reliance on sending unit accuracy |

| Safety | Can be more expensive than mechanical gauges |

Best Practices for Implementing Electric Oil Pressure Gauges:

1. Use high-quality wiring and connectors to ensure reliable signal transmission.

2. Choose a gauge and sending unit that are compatible with your vehicle's electrical system.

3. Mount the gauge in a visible and accessible location.

4. Regularly inspect the wiring and connections for damage or corrosion.

5. Test the gauge and sending unit periodically to ensure proper function.

Frequently Asked Questions:

1. What does low oil pressure indicate? Low oil pressure can indicate a variety of problems, including low oil level, a worn oil pump, or bearing wear.

2. What does high oil pressure indicate? High oil pressure can be caused by a faulty pressure relief valve or using the wrong viscosity oil.

3. How do I test my oil pressure gauge? You can test the gauge by using a mechanical oil pressure tester.

4. How often should I check my oil pressure? You should check your oil pressure regularly, ideally every time you check your oil level.

5. Can I install an electric oil pressure gauge myself? Yes, with basic mechanical skills, you can install an electric oil pressure gauge.

6. What are the symptoms of a bad oil pressure sending unit? Symptoms of a bad sending unit include fluctuating or inaccurate gauge readings.

7. How do I choose the right oil pressure gauge for my vehicle? Consult your vehicle's owner's manual or a qualified mechanic to determine the correct gauge for your application.

8. Where can I buy an electric oil pressure gauge and sending unit? Automotive parts stores and online retailers carry a wide selection.

Tips and Tricks:

Use dielectric grease on electrical connections to prevent corrosion.

Route wiring away from heat sources to prevent damage.

In conclusion, the electric oil pressure gauge and sending unit are essential components for maintaining engine health. They provide a vital window into the inner workings of your engine, alerting you to potential problems before they become catastrophic. Understanding their function, benefits, and potential issues empowers you to take proactive steps in preserving the lifeblood of your vehicle. Regular monitoring, coupled with a proactive approach to maintenance, will help ensure that your engine purrs smoothly for years to come. Investing in a quality electric oil pressure gauge and sending unit is an investment in the longevity and performance of your vehicle. Don't underestimate the importance of this silent sentinel, for it plays a crucial role in keeping your engine running smoothly and reliably. Take the time to understand your vehicle's needs and invest in the tools that will help you keep it running at its best.

Cbbe not working fallout 4 vortex

Rocks pantheon exploring rolling stones greatest albums

Unlocking the magic colors that harmonize with blue and green