Understanding the Distributor Cap and Rotor: A Comprehensive Guide

Ever wondered about the magic that sparks your engine to life? It's not magic, it's precise engineering. One key component responsible for this orchestrated spark delivery is the distributor cap and rotor. This seemingly simple assembly plays a critical role in internal combustion engines, ensuring the correct timing and distribution of high-voltage electricity to each spark plug.

The distributor cap and rotor work together seamlessly. Imagine the distributor cap as a central hub, with wires leading to each spark plug. The rotor, spinning inside the cap, acts as a rotating switch, directing the high-voltage current from the ignition coil to the correct spark plug wire at precisely the right moment. Understanding this dynamic duo is crucial for any car enthusiast or DIY mechanic.

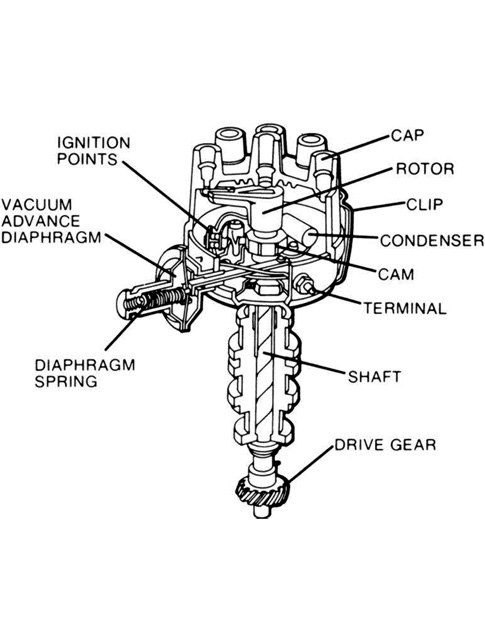

Delving into the distributor cap and rotor diagram reveals a simple yet elegant design. The cap, typically made of durable plastic, houses the terminals for the spark plug wires and a central terminal for the coil wire. The rotor, often made of a conductive material, sits beneath the cap and rotates on a shaft, making contact with each terminal in sequence. This synchronized dance of electricity is what ignites the fuel-air mixture in your engine's cylinders.

The history of the distributor cap and rotor can be traced back to the early days of the automobile. Before electronic ignition systems took over, mechanical distributors, with their caps and rotors, were the standard. They represented a significant advancement over earlier ignition systems, offering more precise timing and improved engine performance. While modern cars have largely transitioned to electronic ignition, understanding the principles of the distributor cap and rotor remains valuable for working on older vehicles.

The importance of a properly functioning distributor cap and rotor cannot be overstated. A faulty cap or rotor can lead to a range of issues, from misfires and rough idling to reduced power and even a complete engine stall. Understanding how to diagnose and address these problems is essential for maintaining a smoothly running engine. Common issues include cracks in the cap, corrosion on the terminals, and wear on the rotor tip, all of which can disrupt the flow of electricity and cause ignition problems.

A distributor cap's function is to distribute high voltage from the ignition coil to the spark plugs in the correct firing order. The rotor, driven by the distributor shaft, rotates inside the cap, making contact with each terminal inside the cap, thereby directing the high voltage to the corresponding spark plug wire.

Example: In a four-cylinder engine, the rotor will make one full rotation for every two rotations of the crankshaft. This ensures that each spark plug receives the high voltage at the appropriate time in the engine's cycle.

Benefits of a well-maintained distributor cap and rotor assembly include optimized engine performance, improved fuel efficiency, and reduced emissions.

Advantages and Disadvantages of Distributor Cap and Rotor Systems

| Advantages | Disadvantages |

|---|---|

| Relatively simple design and operation | Wear and tear of mechanical components |

| Cost-effective compared to electronic ignition systems | Susceptible to moisture and corrosion |

| Easy to diagnose and repair | Less precise timing compared to electronic ignition |

Best Practices:

1. Regularly inspect the distributor cap and rotor for cracks, wear, and corrosion.

2. Replace the cap and rotor as part of your vehicle’s recommended maintenance schedule.

3. Use dielectric grease on the terminals to prevent corrosion and ensure a good connection.

4. Ensure the cap is securely fastened to prevent moisture intrusion.

5. When replacing the cap and rotor, ensure the correct firing order is maintained.

FAQs:

1. What are signs of a bad distributor cap? Misfires, rough idling, reduced power, and difficulty starting.

2. How often should I replace the distributor cap and rotor? Consult your vehicle's owner's manual.

3. Can a bad distributor cap cause a car not to start? Yes, it can.

4. What does a distributor cap do? Distributes high voltage to the spark plugs.

5. What does a distributor rotor do? Directs the high voltage to the correct spark plug wire.

6. How do I know if my distributor rotor is bad? Look for wear, burning, or cracks.

7. Can I replace just the distributor cap or do I need to replace the rotor too? It’s generally recommended to replace both at the same time.

8. Where is the distributor cap located? Typically on the engine, often near the firewall.

Tips and Tricks:

When installing a new distributor cap and rotor, take a photo of the wiring connections before disconnecting anything. This can save you a lot of headaches later. Also, make sure the engine is cool before working on the distributor cap to avoid burns.

In conclusion, the distributor cap and rotor, despite being relatively simple components, play a vital role in the smooth operation of an internal combustion engine. Understanding their function, the importance of a distributor cap and rotor diagram, and implementing best practices for maintenance can help keep your engine running smoothly and efficiently. By recognizing the signs of a failing cap and rotor, you can address potential problems early on, preventing more significant issues down the road. Regular inspection and timely replacement of these crucial components contribute significantly to the overall health and longevity of your engine. Taking the time to familiarize yourself with this essential part of your vehicle’s ignition system will empower you to maintain optimal performance and avoid unexpected breakdowns. So, next time you hear your engine purr to life, remember the silent but essential work of the distributor cap and rotor, ensuring that every spark ignites the power within.

Visualizing compliance the power of showing not just telling

Boost your car audio upgrading your factory stereo with an amplifier

Long stem pampas grass the elegant touch for modern decor