Unlocking the Power: A Deep Dive into 3-Phase Induction Motor Components

Ever wondered how the ubiquitous electric motor powering our industries and homes actually works? The answer often lies within the ingenious design of the 3-phase induction motor. Its widespread use stems from its robustness, simplicity, and cost-effectiveness. Understanding the key components of a 3-phase induction motor is vital for anyone working with or studying these powerful machines.

At the heart of every 3-phase induction motor are a few essential components working in harmony. These parts, meticulously designed and assembled, enable the conversion of electrical energy into mechanical power. We'll delve into the core elements that make these motors tick, from the stationary stator to the rotating rotor, and explore how their interaction generates motion.

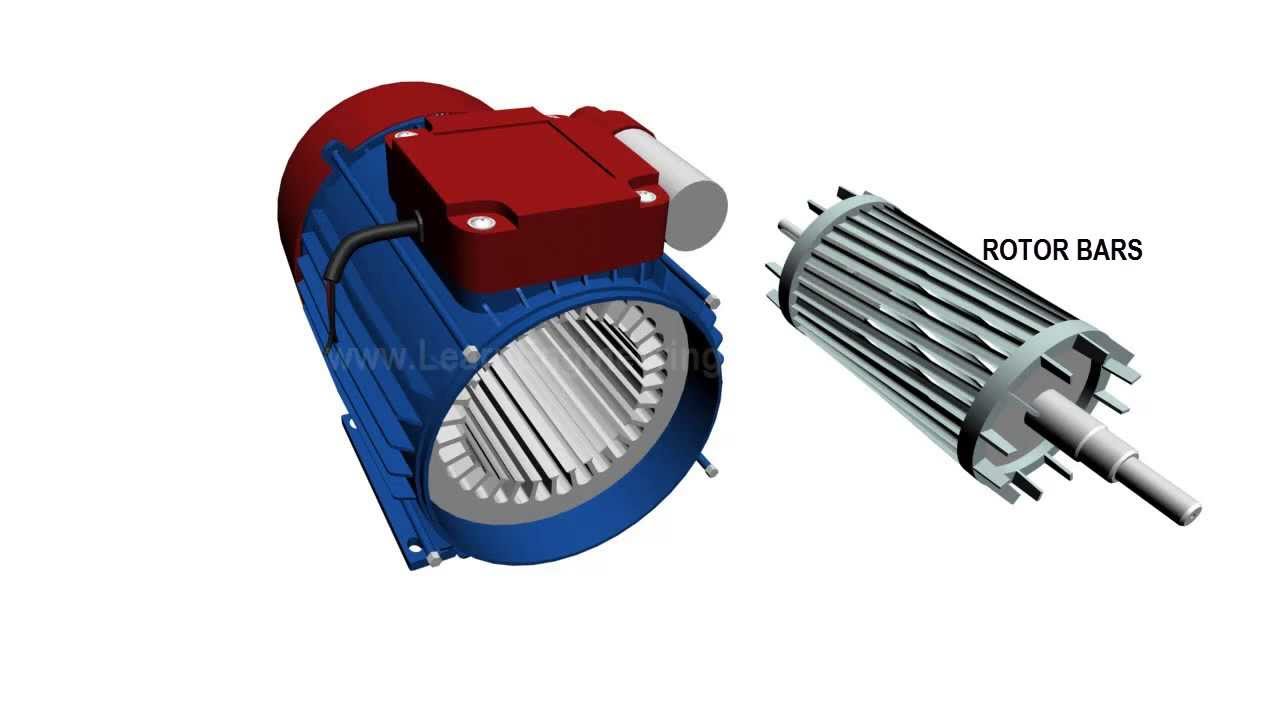

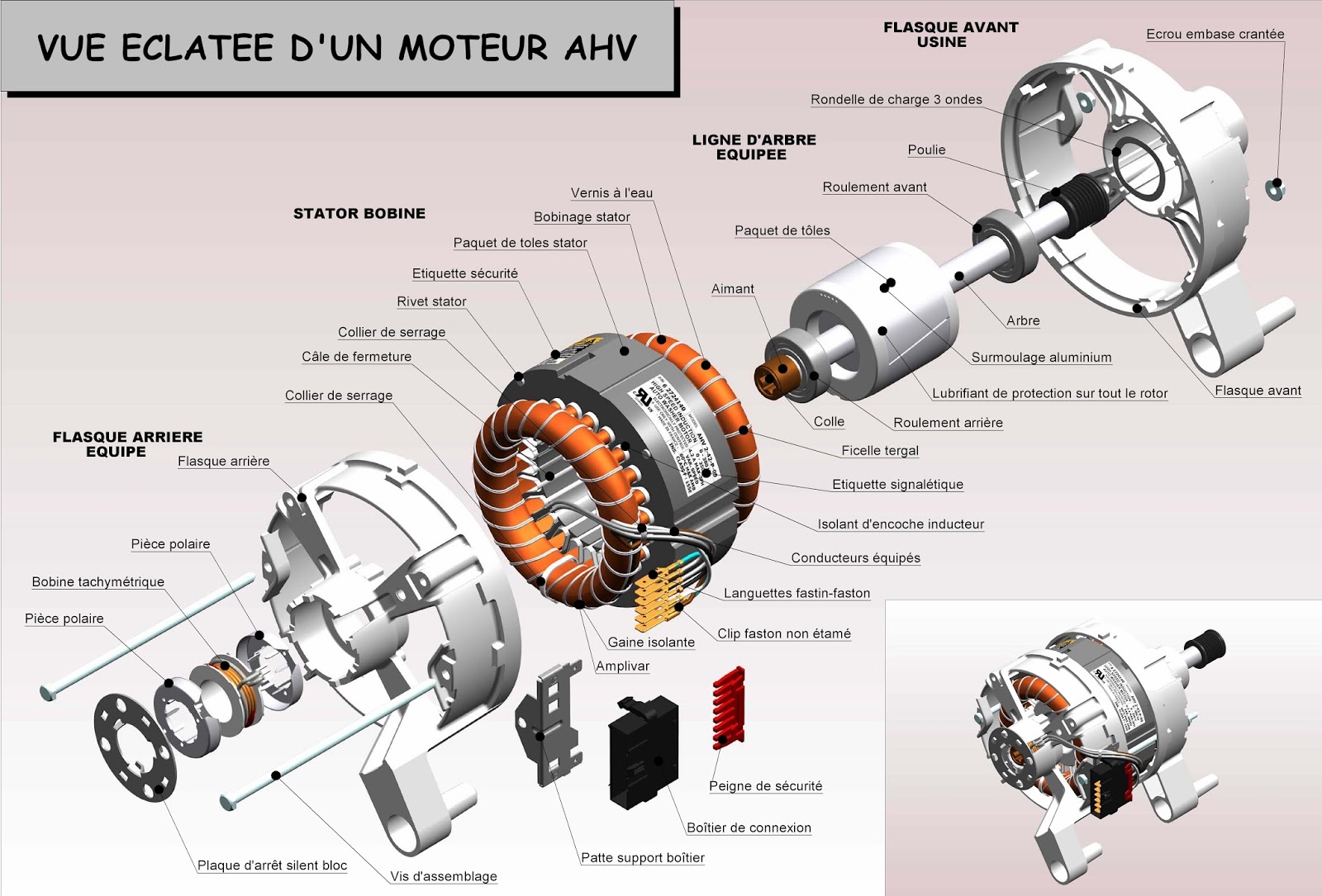

Imagine the 3-phase induction motor as a sophisticated dance between magnetic fields. The stator, the stationary outer part, houses windings that, when energized with a 3-phase power supply, create a rotating magnetic field. This rotating field interacts with the rotor, the inner rotating part, inducing currents within its conductors. These induced currents, in turn, create a magnetic field in the rotor, which interacts with the stator's rotating field, causing the rotor to spin.

The history of the 3-phase induction motor can be traced back to the late 19th century, with pioneers like Galileo Ferraris and Nikola Tesla laying the groundwork for its development. Their contributions revolutionized industrial processes, paving the way for electric-powered machinery and shaping the modern world we live in today. The significance of understanding the individual 3-phase induction motor components has only grown with time, as industries rely heavily on these motors for various applications.

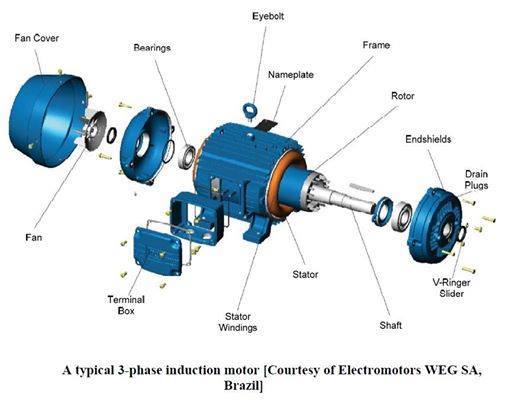

One of the most common issues encountered with 3-phase induction motors is bearing failure. The bearings support the rotor shaft and allow it to rotate freely. Regular maintenance and lubrication are essential to prevent premature wear and tear. Other common challenges include insulation breakdown in the windings, rotor bar cracks, and cooling system inefficiencies, all stemming from issues with specific motor components.

The stator core, typically made of laminated steel, provides a low-reluctance path for the magnetic flux. The rotor, often consisting of aluminum or copper bars embedded in a laminated core, interacts with the stator's rotating magnetic field. The air gap between the stator and rotor is crucial for efficient operation, while the end shields house the bearings and protect the internal components.

Benefits of understanding the individual components include improved troubleshooting, better maintenance practices, and enhanced motor performance. For example, recognizing the signs of bearing wear allows for timely replacement, preventing costly downtime. Similarly, understanding the cooling system's operation helps optimize its efficiency, extending the motor's lifespan.

Advantages and Disadvantages of Specific 3-Phase Induction Motor Components

| Component | Advantages | Disadvantages |

|---|---|---|

| Squirrel Cage Rotor | Simple and robust, low cost | Limited starting torque control |

| Wound Rotor | High starting torque, speed control | More complex and expensive |

Best Practices:

1. Regularly inspect bearings for wear and tear.

2. Ensure proper lubrication of bearings.

3. Monitor motor temperature to prevent overheating.

4. Keep the motor clean and free from debris.

5. Conduct periodic insulation tests on the windings.

FAQs:

1. What is the function of the stator? (Creates a rotating magnetic field)

2. What is the role of the rotor? (Rotates due to interaction with the stator's field)

3. Why is the air gap important? (Influences magnetic flux and motor efficiency)

4. What are the different types of rotors? (Squirrel cage and wound rotor)

5. How does the cooling system work? (Typically uses fans or other methods to dissipate heat)

6. What are common causes of motor failure? (Bearing failure, insulation breakdown)

7. How can I improve motor efficiency? (Proper maintenance, optimal cooling)

8. What are the different types of 3-phase induction motors? (Various classifications based on design and application)

Tips and Tricks:

Use vibration analysis to detect bearing problems early.

Employ thermal imaging to identify hot spots in the motor.

In conclusion, understanding the parts of a 3-phase induction motor is essential for maximizing its performance, reliability, and lifespan. From the stator generating the rotating magnetic field to the rotor converting this field into mechanical motion, each component plays a crucial role. By grasping the function of these individual parts, we can effectively troubleshoot issues, implement preventative maintenance strategies, and optimize the motor's operation. This knowledge translates to reduced downtime, lower operating costs, and increased productivity in various industrial applications. Take the time to delve deeper into the specifics of each component, and you'll unlock a wealth of knowledge that will empower you to effectively utilize and maintain these powerful machines, driving efficiency and success in your endeavors.

Witness the spirit powerful images of palm sunday celebrations around the world

Nicole sittre officer arrested

Slay the digital world cute usernames for black girls