Yamaha 20 HP Outboard Water Pump Impeller: Essential Guide

Is your Yamaha 20 HP outboard overheating? A failing water pump impeller could be the culprit. This critical component is the heart of your outboard's cooling system, and understanding its function is crucial for maintaining peak performance and preventing costly repairs. This comprehensive guide will delve into everything you need to know about the Yamaha 20 HP outboard water pump impeller, from its purpose to troubleshooting common problems.

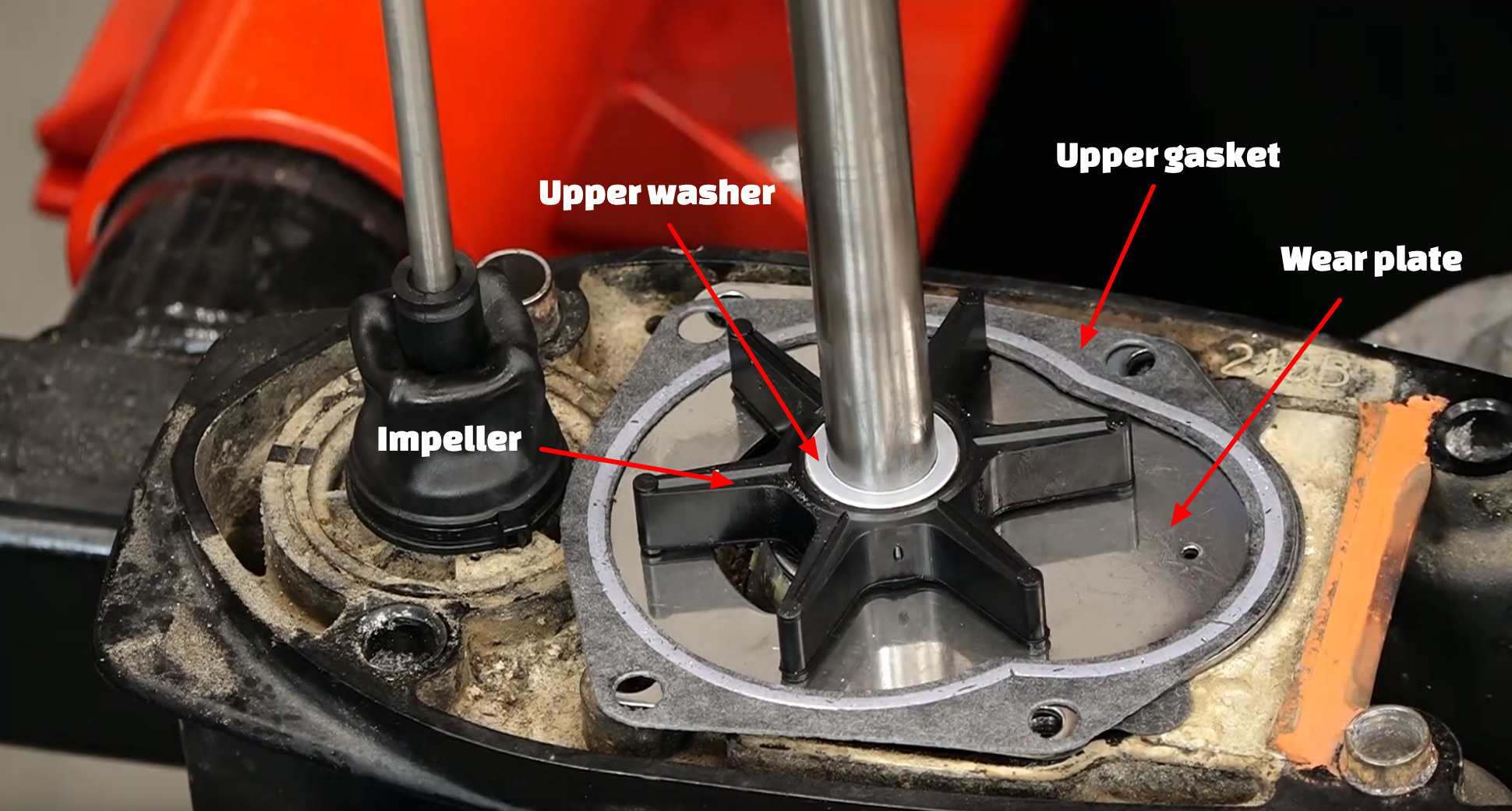

The impeller for a Yamaha 20 HP outboard motor is a small, rubber component located within the water pump housing. It spins rapidly, driven by the engine's driveshaft, drawing cooling water from the lower unit and circulating it through the engine block. This process dissipates heat generated by the combustion process, preventing overheating and potential engine damage. Without a properly functioning water pump impeller, your outboard motor is at risk.

Regular maintenance and timely replacement of the water pump impeller are essential. Over time, the impeller vanes can wear down, crack, or become damaged due to debris, leading to reduced cooling efficiency. A worn impeller can lead to overheating, engine damage, and even complete engine failure. Knowing the signs of a failing water pump impeller and how to replace it can save you significant time and money in the long run.

Identifying a failing impeller involves looking for specific indicators. Overheating is the most obvious sign. You might notice steam or unusually hot water exiting the tell-tale. Reduced water pressure from the tell-tale stream is another warning sign. In some cases, you might even hear a high-pitched whine coming from the lower unit, indicating a worn or damaged impeller. If you experience any of these symptoms, it's crucial to inspect your water pump impeller immediately.

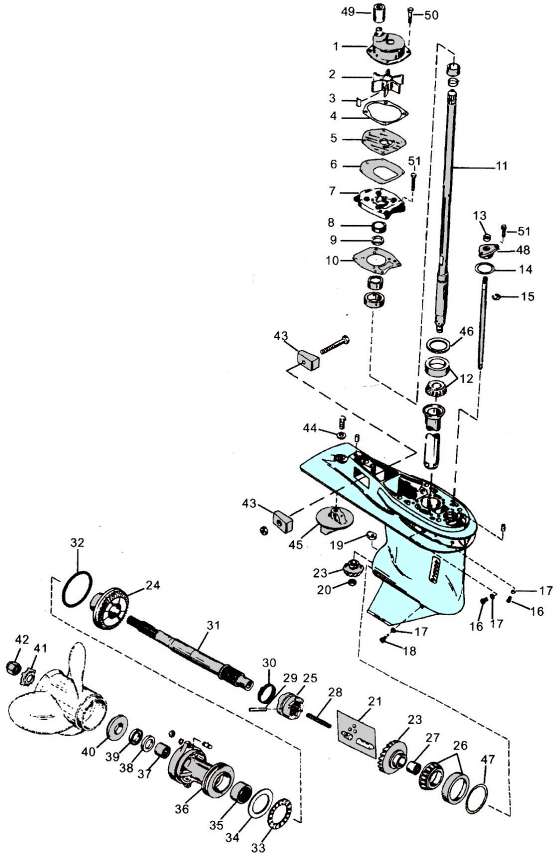

Replacing a Yamaha 20 HP outboard water pump impeller is a relatively straightforward process, even for those with limited mechanical experience. You'll need a few basic tools and a new impeller kit, which you can readily purchase from marine supply stores or online retailers. Following a step-by-step guide and taking the necessary precautions ensures a smooth and successful replacement process. This preventative maintenance can significantly extend the lifespan of your outboard motor.

The history of outboard motor cooling systems parallels the development of the outboard motor itself. Early outboards relied on simple, direct cooling methods. As engine power increased, so did the need for more efficient cooling systems. The evolution of the water pump impeller was crucial in allowing outboard motors to become more powerful and reliable.

The Yamaha 20 HP outboard water pump impeller, specifically designed for this engine type, plays a vital role in its performance and longevity. Its importance lies in maintaining optimal operating temperatures, preventing overheating, and ensuring the engine's smooth and efficient operation.

One of the main issues related to water pump impellers is their susceptibility to wear and tear. The constant spinning and contact with water, combined with the potential for debris ingestion, contribute to the impeller's eventual degradation. Regular inspections and preemptive replacement are key to avoiding major problems.

A Yamaha 20 HP outboard water pump impeller typically consists of a rubber hub with flexible vanes. These vanes create suction, drawing water into the pump housing and forcing it through the engine's cooling passages.

Benefits of a properly functioning water pump impeller include optimal engine temperature, extended engine life, and improved performance. A cool engine runs more efficiently and is less prone to damage. A long-lasting impeller contributes to the overall reliability of the outboard.

Advantages and Disadvantages of OEM vs. Aftermarket Impellers

| Feature | OEM Impeller | Aftermarket Impeller |

|---|---|---|

| Quality | Typically higher quality materials and construction | Quality can vary significantly between brands |

| Price | More expensive | Often more affordable |

| Fit | Guaranteed to fit your specific engine | Fit may be an issue with some brands |

A simple action plan for impeller maintenance: inspect annually, replace every 2-3 years, or sooner if signs of wear are present. Carry a spare impeller kit onboard for emergencies.

Frequently Asked Questions:

1. How often should I replace my impeller? Every 2-3 years or as needed.

2. What are the signs of a failing impeller? Overheating, weak tell-tale stream, whining noise.

3. Can I replace the impeller myself? Yes, with basic tools and a repair manual.

4. What tools do I need to replace the impeller? Screwdrivers, wrench, pliers, impeller housing puller (if necessary).

5. Where can I buy a replacement impeller? Marine supply stores, online retailers.

6. What is the importance of using the correct impeller for my engine? Proper fit and performance.

7. How can I prevent impeller damage? Flush the engine after each use, avoid running in shallow water.

8. What happens if I run my outboard with a damaged impeller? Overheating, engine damage.

Tips and Tricks: Apply waterproof grease to the impeller shaft during installation to aid in future removal. Inspect the impeller housing for wear or damage during replacement. Use a genuine Yamaha impeller for optimal performance and longevity.

In conclusion, the Yamaha 20 HP outboard water pump impeller is a small but vital component. Its proper function is crucial for maintaining engine health, performance, and longevity. Regularly inspecting and replacing your impeller is a cost-effective way to prevent potentially catastrophic engine damage. Understanding the function, maintenance, and troubleshooting of this essential component will empower you to keep your Yamaha outboard running smoothly for years to come. Don’t wait until it’s too late – prioritize impeller maintenance and enjoy uninterrupted boating adventures. By investing a little time and effort in preventative maintenance, you'll reap the rewards of a reliable and dependable outboard motor. Take action today and ensure your next boating trip is a success!

Taming the fuel gauge mastering the fuel sending unit connection

Conquer bilge water the ultimate guide to float switch installation

Obituaries sunset funeral home